We're an Embedded Award 2026 Tools nominee and would love your support! Vote for C/C++test CT >>

Explore the Chapters

Safety-critical software development standards recommend that manufacturers prove that the tools they’re using to develop software don’t introduce issues and do provide correct, predictable results.

The process of providing such evidence is known as tool qualification. While it’s a necessary process, tool qualification is often a tedious and time-consuming activity for which many organizations fail to plan. To make this painless, select tools are certified and have a history of being used in the development of safety-critical applications.

In the case of airborne systems software development, DO-330, Software Tool Qualification Considerations, provides guidance on tool qualification. The purpose is to provide a framework for a tool qualification life cycle that includes planning, verification, quality assurance, and documentation. There are different levels of tool qualification from 1 to 5, with 5 being the least rigorous. The level is based on the possible impact of the tool on system safety.

Here are some of the key steps involved in tool qualification, according to DO-330.

The end deliverable is proof in the form of documentation. The qualification process outlined in DO-330 is complex and time consuming. Parasoft’s Qualification Kits for C/ C++test includes a convenient tool wizard that brings automation into the picture and reduces the time and effort required for tool qualification.

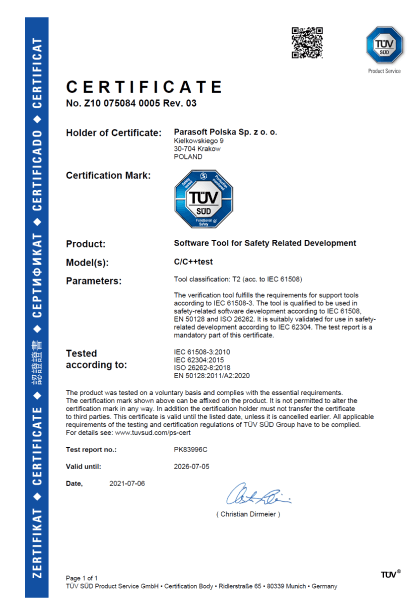

Parasoft C/C++test and C/C++test CT TÜV SÜD certificate

Tool qualification needs to start with tool selection to ensure that you’re using a development tool that’s certified by an organization like TOV SOD. This will significantly reduce the effort when it comes to tool qualification.

Parasoft C/C++test, C/C++test CT, and DTP are certified by TOV SOD for functional safety according to IEC, ISO, and other functional safety industry standards for both host based and embedded target applications. Though the certificate is not enough for RTCA DO-178C/DO-330, it demonstrates a historical commitment by Parasoft in providing quality products.

To satisfy DO-330 tool qualification requirements, C/C++ software development paves the way for a streamlined qualification of static analysis, unit testing, and coverage requirements for the safety-critical standards by offering a tool qualification kit that automates the tool qualification process for any development host and/or target ecosystem.

Traditionally, tool qualification has meant significant amounts of manual labor, testing, and documenting to satisfy a certification audit. But this documentation-heavy process requires manual interpretation and completion. As a result, it’s time consuming and adds to an organization’s already heavy testing schedule and budget.

Parasoft leverages its own software test automation tool qualification with Qualification Kits, which include a documented workflow to dramatically reduce the amount of effort required.

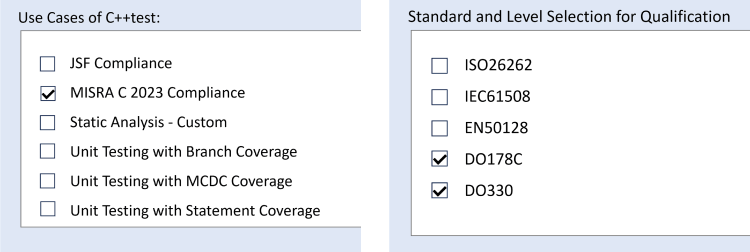

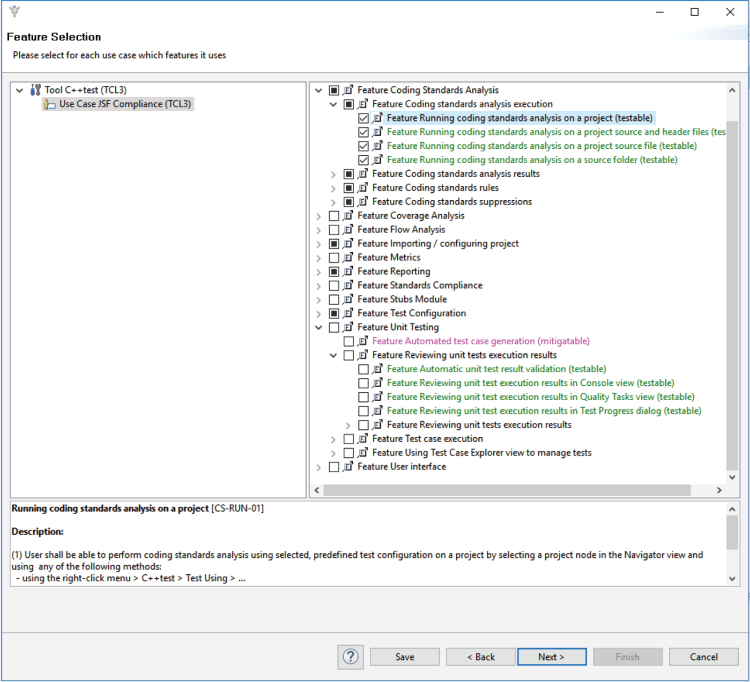

There should be no need to do any extra work for qualifying capabilities not used during development. Reducing the scope of testing, reporting, and documentation is a key way to reduce the qualification workload.

For example, as part of the DO-178C/DO-330 tool qualification kit and process, users can select Parasoft C/C++test for static analysis of C/C++ code to check its compliance to the MISRA C:2023 standard. The tool then selects only the parts of the qualification suite needed for this function.

Parasoft Qualification Kits allow users to select the options required for their project. Upon selection, only tests and documentation are used and provided from this point forward.

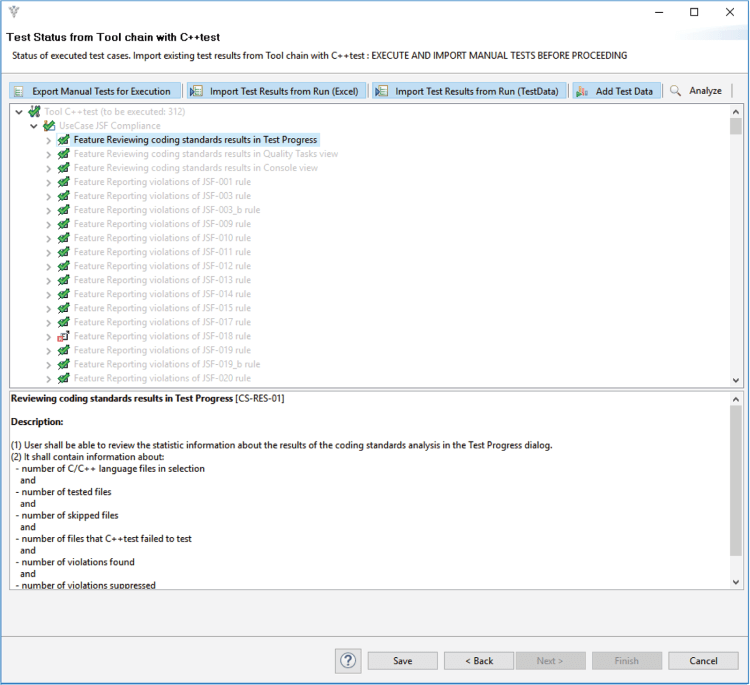

A unique advantage to qualifying test automation tools is that the tools can be used to automate their own testing. Automating this as much as possible is key to making it as painless as possible. Even manual tests, which are inevitable for any development tool, are handled as efficiently as possible. Step by step instructions are provided and results are entered and stored as part of the qualification record.

Parasoft C/C++test collects and stores all test results from each build. Tests run as they do for any type of project. These results are brought into the test status wizard in the Parasoft Qualification Kits to provide a comprehensive overview of the results like those shown below.

Leveraging centralized data collection and automating the qualification process greatly reduces manual tracking of the compliance progress.

Every development tool has known bugs and any vendor selling products for safety- critical development must have these documented. There’s more to dealing with known defects than just documenting them.

Tool qualification requires proof that these defects are not affecting the results used for verification and validation. For each known defect, the manufacturer must provide a mitigation for each one and document it to the satisfaction of the certifying auditor.

It’s incumbent on the tool vendor to automate the handling of known defects as much as possible. After all, the vendor is expecting customers to deal with third-party software bugs as part of their workload!

The Parasoft C/C++test Qualification Kits include a wizard to automate the recording of mitigation for known defects as shown in the example below.

In each of these documents, only the documentation required for the tool featured in use is generated because the scope of the qualification was narrowed down at the beginning of the project. Teams greatly reduce the documentation burden with automation and narrowing the qualification scope.